DC MAXI FLEX

DC MAXI FLEX is Dancutter’s most powerful cutter.

Size range: 100 – 400 mm, 4″ – 16″ (with centring tool set)

It has an extremely powerful motor which makes the cutter both fast and efficient. The DC MAXI FLEX is flexible and can go through several 45° bends in a 150 mm pipe and works effortlessly whether the pipe is straight or has bends.

Control Unit is included.

Enquire about this product

1/

DC MAXI FLEX

Key features

Dancutter’s Most Powerful Cutter

If you are mostly working in larger pipes, DC MAXI FLEX is your right choice for reopening laterals or removing hard deposits like concrete.

Advanced Control Unit

Experience smooth and effortless control of your cutter with Dancutter's DC SUPER FLEX and DC MAXI FLEX control unit. Equipped with two joysticks, the control unit provides precise control over the motor rotation and cutter arm movements, allowing you to raise, lower, expand, and contract the cutter with ease.

High Manoeuvrability

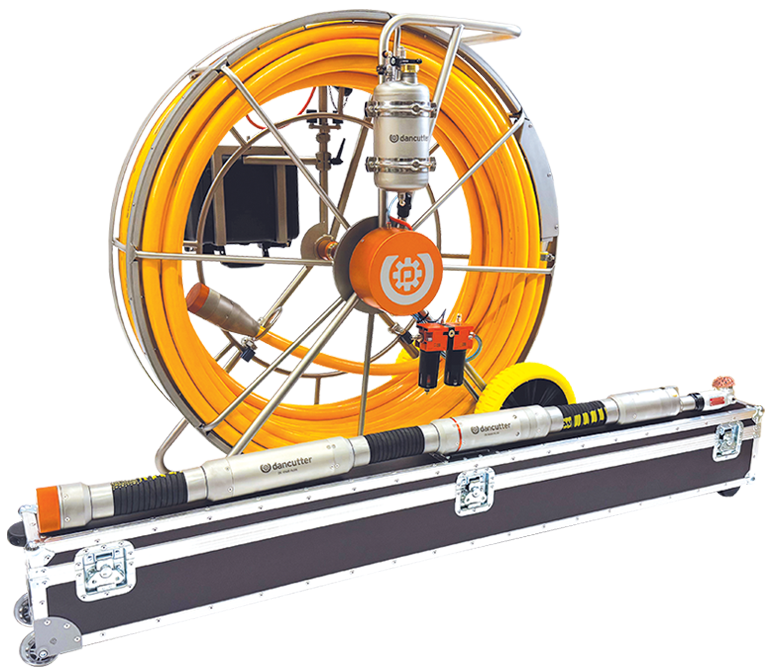

Automatic feeder and built-in slip ring for seamless back-and-forth movement.

360º Continuous Rotation

Enjoy unrestricted operation with a continuous 360-degree continuous rotation feature.

Enhanced Functionality

The cutter is equipped with a spray nozzle for camera cleaning with air or fluid.

Specification

Download spec sheet-

Pipe Dimensions

Dia. 150 - up to 400mm, 4" - 16" (with centring tool set)

-

Supply Hose

70 metres, 230 ft

-

Flexible

45º in a 150mm, 6" pipe

-

Expansion / Contraction

150mm - 6"

-

Rotation

360º Continuous Rotation

-

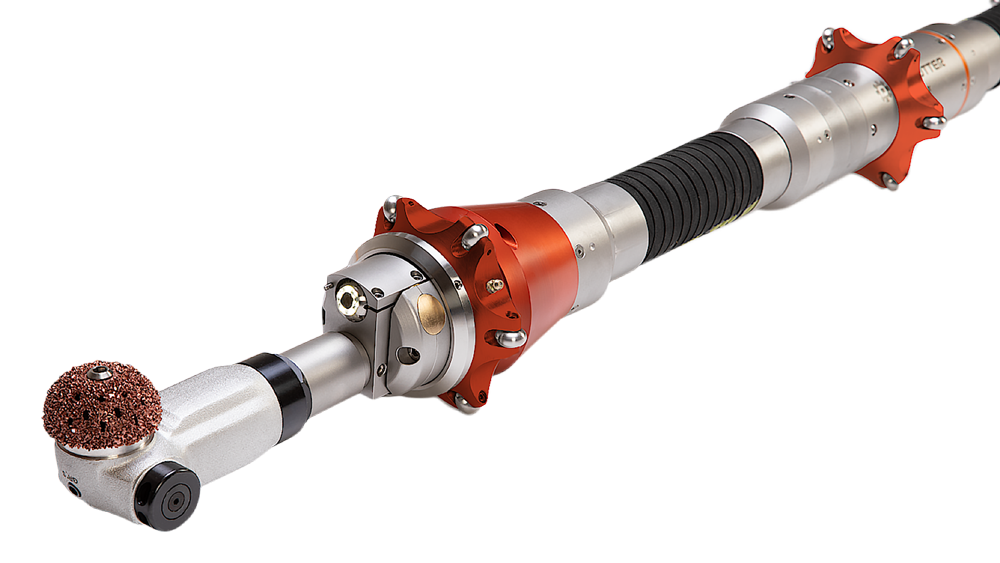

Grinds, Mills and Cuts

PVC. Liner, Concrete, Iron, Cast Iron, Stainless Steel

Need help finding the right cutter?

We are ready to answer your questions.

Videos

How to Mount a MAXI FLEX Centring Tool Set

Dancutter’s Most Powerful Cutter

Download spec sheet

DC MAXI FLEX is Dancutter’s most powerful cutter. It has an extremely powerful motor which makes the cutter both fast and efficient. The DC MAXI FLEX is flexible and can go through several 45° bends in a 150 mm pipe and works effortlessly whether the pipe is straight or has bends.

If you are mostly working in larger pipes, DC MAXI FLEX is your right choice for reopening laterals or removing hard deposits like concrete.

When you are cutting, milling, and grinding in pipes from 100 – up to 400 mm / 4” – 16”, DC MAXI FLEX is a powerful solution whether the pipe is made of PVC, concrete, cast iron, or steel.

Maintenance requirements for the DC MAXI FLEX are kept to a minimum, thanks to its superior construction using high-quality stainless steel. It features an oil lubricator and water separator, ensuring optimal performance. To enhance efficiency, we recommend using a refrigerated dryer on the compressor, reducing the water content in the air to below 20 g/m3. This practice ensures the cutter operates in a clean, dry environment, maximizing efficiency and extending its service life.

- Great flexibility in navigating several 45° bends.

- Efficient in various cutting, milling and grinding tasks and materials.

- User-friendly control system.

- Toolbox, centring tool with brushes and transport box are standard accessories.

The DC MAXI FLEX is designed for single-person operation. Its setup is swift and straightforward, allowing for quick transitions between tasks. The wheeled stainless-steel frame holds the supply hose, control unit, and cutter, ensuring everything is at arm’s reach. Always ground the equipment for safety, especially when using the grinder in dry pipes, to prevent static electricity hazards. Elevate your cutting capabilities with the DC MAXI FLEX – the ultimate choice for superior efficiency in pipe cutting.